Commissioning and Management of a Fully Automatic Potato Flakes Packaging Line: Continuous Improvement in Production Packaging

Optimizing packaging line and setting new standards in the continuous improvement industry

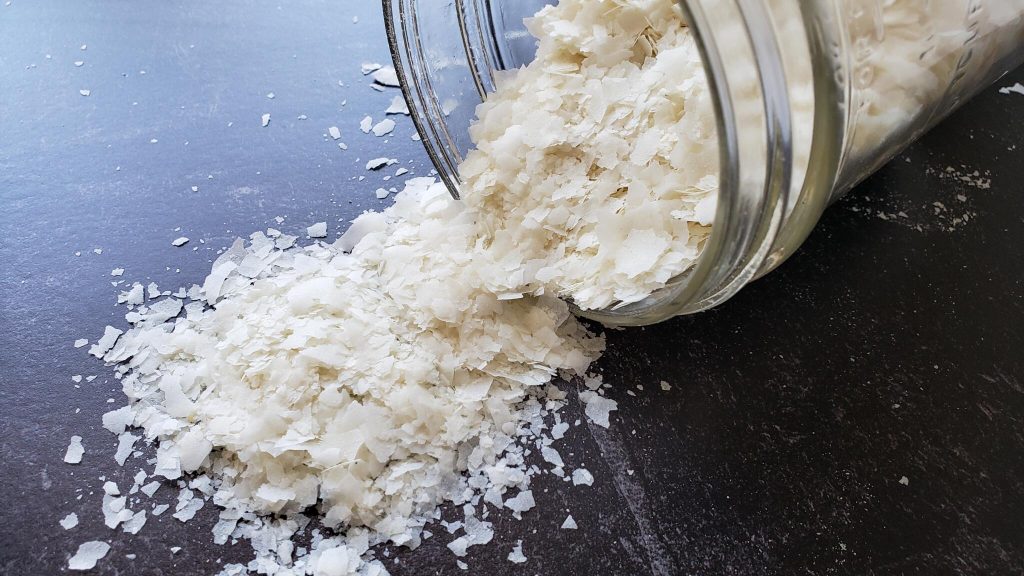

In the ever-evolving world of food production, our client, a renowned name in frozen fries, embarked on a new journey in 2022: the production of potato flakes.

However, the transition wasn’t without its challenges. With our expertise, our client overcame these hurdles, optimizing their packaging line and setting new standards in the continuous improvement industry.

Our client, while a master in frozen fries, was stepping into unfamiliar territory with potato flakes. The initial phase was riddled with challenges, from unreliable machinery to a workforce unacquainted with the nuances of digital machinery.

Challenges faced

- Project Disruptions: Key engineers, pivotal to the project, departed midway, causing significant delays and a disconnect with suppliers.

- Machine Reliability: Our client grappled with machinery that couldn’t meet production rates or maintain the quality standards their customers expected. This was uncharted territory for both our client and their machine suppliers.

- Workforce Adaptation: Long-time operators, accustomed to manual machinery, faced a steep learning curve with the new semi-automatic machines. Their pace of learning and resistance to change posed significant challenges.

Our strategic approach

Otofacto stepped in with a holistic strategy, focusing on both the technical and human aspects of the project:

- Supplier Collaboration: We engaged with suppliers across Europe, challenging them to enhance machine performance and meet stringent specifications.

- Stakeholder Coordination: Ensuring seamless communication between internal teams and external partners was paramount.

- Continuous Training: We prioritized operator training, introducing them to best packaging practices and the intricacies of the new machinery.

- Embracing Continuous Improvement: Deployment of industry-leading practices like 5S and SMED, coupled with the introduction of a PML1 system and advanced training for maintenance technicians, set the stage for sustained growth.

Outstanding Results of Continuous Improvement Solutions

Our collaborative efforts bore fruit:

- A remarkable increase in packaging output, from 480 Tons/month in September 2022 to 2100 Tons/month by June 2023.

- Quality enhancements, notably addressing sealing issues with finished product bags.

- A significant reduction in downtime, dropping from 450 hours/month to a mere 120 hours.

In the realm of maintenance and optimizing machine performance to improve productivity, our expertise shines through.

Continuous Improvement in Production Packaging results in downtime reduction (-73%) and packaging output increase (+338%)

Digital transformation in manufacturing

Discover what Continuous Improvement Solutions can bring to your industry. Our client’s success story is a testament to our commitment to driving digital transformation in the manufacturing industry.