#ImprovingOEE | #Digitalization | #IIoT Solution | #Advanced Analytics | #MLOps | #Preventive Maintenance | #Digital Transformation

Table of contents

About the Client

Miele is a German-based manufacturer. Widely known for its range of premium household appliances, including washing machines, dishwashers, refrigerators, ovens, vacuum cleaners, and more.

The company’s product portfolio caters to both residential and commercial markets, offering state-of-the-art solutions that enhance everyday life and meet the needs of various industries. In the 2021 financial year the company achieved sales of 4.84 billion euros and employed around 22,000 people worldwide.

Goals of our client

- Lower the rate of rejects of glazing machines.

- Find reasoning behind different damage patterns that arises during the glazing process.

- Increase efficiency and effectiveness for machine data analysis.

- Enable process engineers and make machine data analysis accessible.

Our IIoT Solution

- Connect production devices (glazing machines) to a cloud interface.

- Stream data in a structured way into Azure Databricks

- Perform large scale statistical analysis for detecting failure patterns.

- Enable process engineers with Self Service BI solutions via PowerBI.

Attained Results

- Reduction of rejects by 30%

- Reduced QA efforts- Reduction in costs

- Three interactive dashboards for process optimization- Harnessing interaction effect and unlocking key insights for greater optimization.

- Preventive maintenance due to self-service anomaly dashboard-

Deep-Dive

Initial Situation

Our client uses plasma glazing machines for coating parts that are installed in ovens. Furthermore, these glazing machines can cause different defect patterns during the coating process causing rejects that cannot be sold to customers.

To uncover why certain defect patters arise, an in-depth analysis of the machine data was needed.

Initially, the data was stored in many distributed Excel sheets. Therefore, each of the data sources were disconnected, and had to be assessed sequentially directly on the production site. Conclusively, It was also not feasible to connect different data sources like:

- process data

- overall equipment effectiveness data

- QA data

These circumstances cause extremely time-consuming investigations in case of errors for the process engineers and very limited insights due to disconnected data.

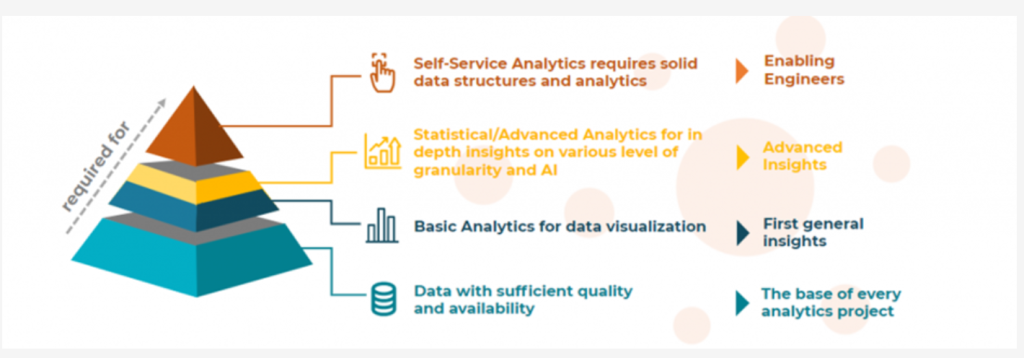

Therefore in order to overcome these shortcomings and improve OEE we facilitated a comprehensive analysis, we set up an IIoT System evolving from a solid data base over tools for statistical analysis to a profound self-service analytics environment.

IIoT System for improving OEE

Figure 1: Steps towards attaining digital maturity and enhanced OEE

Step 1: Consolidate Data

To make all kinds of data from different machines and formats available in one place, the first step was to consolidate data within Databricks for big data analysis.

Methodology- To achieve this step,

machines were connected to a server, that controls the data stream to the cloud.

In addition, data that was then manually stored in Excel sheets or different isolated databases and then loaded to the cloud using Databricks and Azure Data Factory as services for scalable high performance data transfers.

Achieving a 360-degree view on all relevant data sources

To achieve this, data from the production site is streamed to the cloud in real time while some other data sources (e.g., overall equipment effectiveness data) with a slower update rate are now, refreshed batch wise once per day.

Step 2: Unlock Big Data Analytics

To gain the most insights from the consolidated database, Databricks offers a variety of different computing clusters ranging from very small units with one node and modest computing power and storage to very powerful clusters with many workers, terabytes of ram, and extensive scalability options.

Independent of the size, a cluster can be created and started within minutes and shut down after achieving the purpose. Thus, we setup a Databricks environment to make extensive statistical analysis possible and foster applications of machine learning.

The analysis highlights various quick wins and/or pain points which are utilized advantageously. Furthermore, our IAT analyses the technical aspects from the collected data and provides valuable insights to the end-users, people on the shopfloors.

Step 3: Improving OEE at Scale

A very important aspect of successful IIoT system development is to guarantee scalability. Likewise, for our client, we started a PoC with only one glazing machine while in the final production environment, there were seven machines connected to the cloud environme

The following aspects were key to enable fast and easy scaling:

A gateway server (Kepware), controlling the data being streamed to the cloud. Using this service allows the user to control which machines should be connected to the cloud and which data should be send for every machine. With just a few clicks, new machines can be connected to the Azure.

The Azure IoT Hub receives the data from the gateway server and stores it for a desired period, during which the data can be received from a streaming service.

Spark Structured Streaming combined with Databricks easily adapts computing power to changing demands.

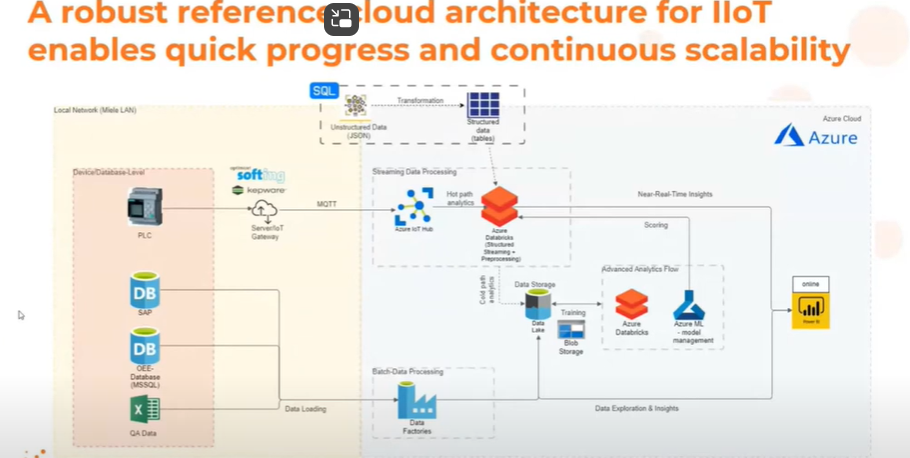

Our standardized approach to IIoT To help our client creating an easily extensible and rapidly scalable IIoT solution, we used our IIoT refence architecture, which can be easily customized to meet our customer’s unique needs.

It provides an end-to-end solution from raw machine data to be structured, individually tailored insights to rigorously improve processes.

To adapt to certain use cases, it provides a lot of flexibility in terms of additional services and scalability.

Step 4: Implementing Self Service Analytics to improve OEE

Once the overview of the seven connected machines, in the next step self-service was enabled.

To bring the power of statistical analysis to the process engineers of our client, we built interactive dashboards to investigate different data sources on a multitude of different levels of granularity.

This allows us to compare e.g., similar charges or search for failure patterns in overall equipment effectiveness data in different temporal resolution.

The tool of choice was in this case PowerBI, which integrates seamlessly with the Azure cloud environment and allows to host resulting dashboards in an online environment where process engineers can access them quickly.

One of our core value proposition is to provide solutions to our clients and not just vague data and dashboards. Hence, our advanced team boils the insights down to actionable steps that can be implemented by the engineers. Since, our teams comes from both the worlds, IT and OT, effective communication is never an issue.

Improving OEE at Miele: integrate in IT, enable Engineering

In addition, to improve OEE further we used clusters along with Machine learning, commonly known as MLOps. This allowed us to enable anomalies detection and preventive maintenance.

Thereby, digitally transforming our clients production!

Conclusion

The client witnessed improvement in OEE as a result of the following:

- 30% reduction of scrap yield costs

- > 50% possible reduction after further analysis

- Real-time display of production data with cloud access

- Analysis of production processes

- Applied IIoT throughout

Moreover, as the insights from data analysis started pouring in, the client had begun witnessing tangible results in the early stages of the project.

Realized ROI in the long-run

It is imperative to realize the true potential ROI from the project by viewing it in the long-run.

Although, plasma coating process is simple and overall well understood from a process technology point of view. The project highlighted its value when viewed from production point of view, the project has been able to empower the client, allowing the client to address key issues, explore new opportunities and realize massive ROI when it comes to improve OEE.

Factors Leading to High ROI

Scalability: After the ideation and PoC, the solution is then scaled. The ambition is to replicate the solution as much as possible. It was witnessed at Miele that our solution had garnered the following results:

The solution was then scaled to similar machines, the attained results would simply multiply. Consequently, this was achieved for the similar 7 machines used at the client.

2) Potential of Reusability- Our IIoT reference architecture includes only highly flexible and scalable services which allows us to extend the initial PoC in a short time with a minimum of cost.

The IIoT architecture

The construction of the architecture was such that many of the elements above could be kept the same. Fundamentally speaking, in most cases only PLCs / method to include data changes but most of the other things remain the same.

Factors leading to cost reduction

Flexibility without the initial cost- Main efforts to build the architecture has been previously done, hence, this gives the client full freedom to develop IIoT projects elsewhere. This tremendously reduces costs, and improves the added value from the project in the Long-run.

Interaction effect- The creation of 3 different dashboards for different roles:

1) Lab operators

2) Machine operators

3) Engineers

This enabled the client to unlock potential, allowing for “unlimited potential”.